![]()

Features

• Adoption of an air type elevator unit allows for the drum to be easily replaced.

• The mechanically operated safety stopper safely and reliably prevents the drum can from falling off.

• A wide range of options is available.

• Performance and installation compatibility with previous drum can pump models.

• Applicable container: 200 kg drum (JIS product)

Specifications

| Model | AELBPR08 | AELBPR10 | AELBPR20 | AELBPR40 | |

| Pump | Discharge quantity (cm3/min(50/60Hz)) |

75/90 | 100/120 | 158/190 | 316/380 |

| Max. operating pressure (MPa) | 21 | ||||

| Safety valve pressure (MPa) | 25 | ||||

| Motor specifications | 0.2 kW (speed reduction ratio 1/59) |

0.2 kW (speed reduction ratio 1/43) |

0.4 kW (speed reduction ratio 1/21) |

||

| Grease used | NLGI #0 to #2 (Note, however, that the consistency will be 240 or more at the operating temperature.) |

||||

| Elevator | Supply air pressure (MPa) | 0.4~0.5 | |||

| Liftable weight (kg) | 80 | ||||

| Total raise stroke (mm) |

950 | ||||

| Total unit weight (kg) | Single line | 185 | |||

| Dual line | 195 | ||||

Note) When replacing the drum can, because the follower plate is tightly attached to the drum, ensure that air is supplied before removal.

Note) Residual grease amount is set at 8 L at the time of shipment. Amount can be changed upon arrival.

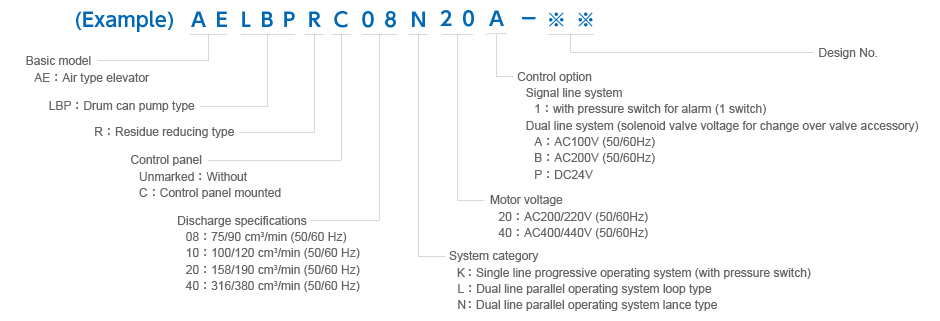

Explanation of Model Symbols