![]()

Features

• Environmentally friendly reduction of waste (90% cut in residual grease compared to our previous models).

• When disposing of used drum cans, grease separation is simple.

• Follower plate allows for safe and easy drum can removal through air injection separation.

• Performance and installation compatibility with previous drum can pump models.

Specifications

| Model | LBPR08 | LBPR10 | LBPR20 | LBPR40 |

| Discharge quantity(cm3/min(50/60Hz)) | 75/90 | 100/120 | 158/190 | 316/380 |

| Max. operating pressure(MPa) | 21 | |||

| Safety valve pressure(MPa) | 25 | |||

| Motor specifications | 0.2 kW (speed reduction ratio 1/59) |

0.2kW (speed reduction ratio 1/43) |

0.4 kW (speed reduction ratio 1/21 |

|

| Grease used | NNLGI #0 to #2 (Note, however, that the consistency will be 240 or more at the operating temperature.) |

|||

| Weight (approx. in kg) | 70 | |||

Note) When replacing the drum can, because the follower plate is tightly attached to the drum, ensure that air is supplied before removal.

Note) Residual grease amount is set at 8 L at the time of shipment. Amount can be changed upon arrival.

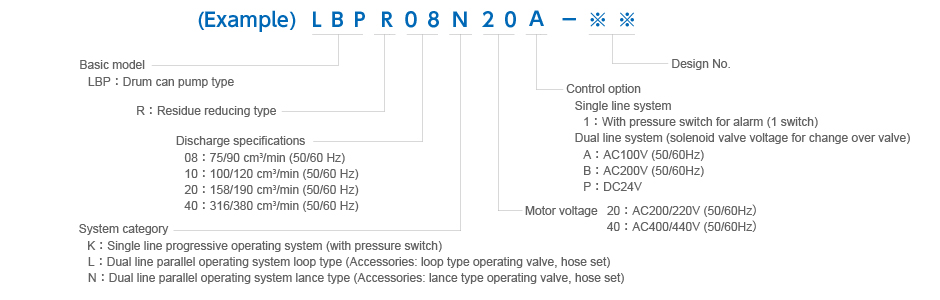

Explanation of Model Symbols