Overview

The open gear of rotary kilns, rod mills, mixers, and chains for pan pelletizers, for example, are lubricated by spraying grease or oil with air at appropriate amount and frequency.

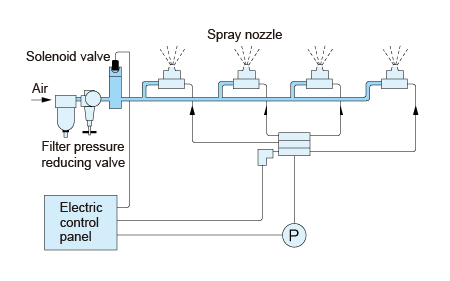

Configuration

This system comprises a pump, control panel, distributing valve, air control equipment, and spray nozzles.

System Operation

The basic operation of this system involves spraying lubricant fed via the pump and distributing valve by air. To prevent the nozzle surface from clogging with lubricant after finishing spraying, only air is sprayed. (This is called “after-blow.”)

Example of Use of Spray Nozzle

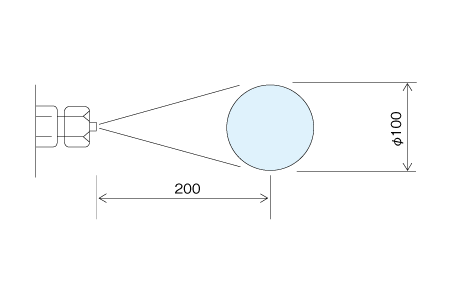

Spray Nozzle Injection Pattern

Specifications

| Model | BSV-3 |

| Pneumatic circuit | Solenoid valve is required for opening and closing air supply circuit. |

| Max. operating pressure (MPa) | Lubricant 5, air 0.5 |

| Min. required amount of oil (cm3) | - |

| Min. operating pressure (MPa) | - |

| Air consumption (NL/min), air supply pressure 0.5 MPa |

120 |

| Weight (kg) | 0.2 |