![]()

Overview

This electric control panel is used on the UE and U type motor driven grease pumps.

This control panel ensures trouble-free operation of centralized lubricating systems, and centrally controls savings in factory manpower through automatic operation.

Features

• The pump is started automatically by the system timer and stops automatically when lubricating is completed.

When an abnormality occurs, the operator is notified by lighting of an alarm lamp and pump operation is stopped at the same time.

EF type ... Dual line system

EA type ... Dual line system

EK type ... Single line centralized lubricating system

Specifications

| Model symbol |

Power supply | Function (all indoor dustproof type) | Applicable pump |

| EF-3 | 200/220 V AC | Pump operation is started when the timer preset time is reached, and is automatically stopped when lubrication is completed. Three types of alarms “Oil feed time extension”, “Tank empty” and “Overload operation” are displayed simultaneously when a fault occurs.Pump operation can also be started whenever desired by the operation switch regardless of the down time timer. |

UEC-108ANP(L) (mechatronics integration type) |

| EF-3T | 400/440 V AC (transformer built-in) |

||

| EF-4 | 200/220 V AC | Three types of alarms “Oil feed time extension”, “Tank Empty” and “Overload operation” are displayed individually when a fault occurs. |

UE-108AN(L) UE-225AN(L) (free-standing type) |

| EF-4T | 400/440 V AC (transformer built-in) |

||

| EA-5 | 200/220 V AC | Pump operation is started when the timer preset time is reached, and is automatically stopped when lubrication is completed. Also, three types of alarms “oil feed time extension”, “Tank Empty” and “Overload operation” are displayed individually when a fault occurs. Pump operation can also be started whenever desired by the pushbutton switch regardless of the down time timer. |

U-25AN(E・L) U-30AN(E・L) U-40AN(E・L) (wall-mounted type) |

| EA-5T | 400/440 V AC (transformer built-in) |

||

| EK-3 | 200/220 V AC | Pump operation is started when the timer preset time is reached, and is automatically stopped when lubrication is completed. The causes of the “Oil feed time extension”, “Tank Empty”, “Overload operation” and “High Pressure Error” alarms are displayed simultaneously as “faults” when a fault occurs. |

AKAC-108AKP type AKAC-108BKP type AKAC-108AK type (mechatronics integration type) |

| EK-3T | 400/440 V AC (transformer built-in) |

||

| EK-4 | 200/220 V AC | Pump operation is started when the timer preset time is reached, and is automatically stopped when lubrication is completed.The “Time over”, “Tank empty”, “Overload operation” and “High Pressure Error” alarms are displayed individually by their cause when a fault occurs. Manual intervention is possible during automatic operation. |

AKA type all models, LBP type (wall-mounted type) |

| EK-4T | 400/440 V AC (transformer built-in) |

||

| EK-5 | 200/220 V AC | Pump operation is started when the timer preset time is reached, and is automatically stopped when lubrication is completed. The “Time over”, “Tank Empty”, “Overload operation” and “High pressure error” alarms are displayed individually by their cause when a fault occurs. Manual intervention is possible during automatic operation. |

AKA type all models, LBP type (wall-mounted type) |

| EK-5T | 400/440 V AC (transformer built-in) |

Remarks

Automatic on-site operation is the standard mode for the electric control panel. Some models also support remote operation and remote display.

• The EN type has a built-in automatic replenisher circuit that operates by a barrel pump.

• For details on the EH type that has a built-in automatic replenisher circuit that operates by batch replenishment, ask us for materials.

Dual Line Electric Control Panel

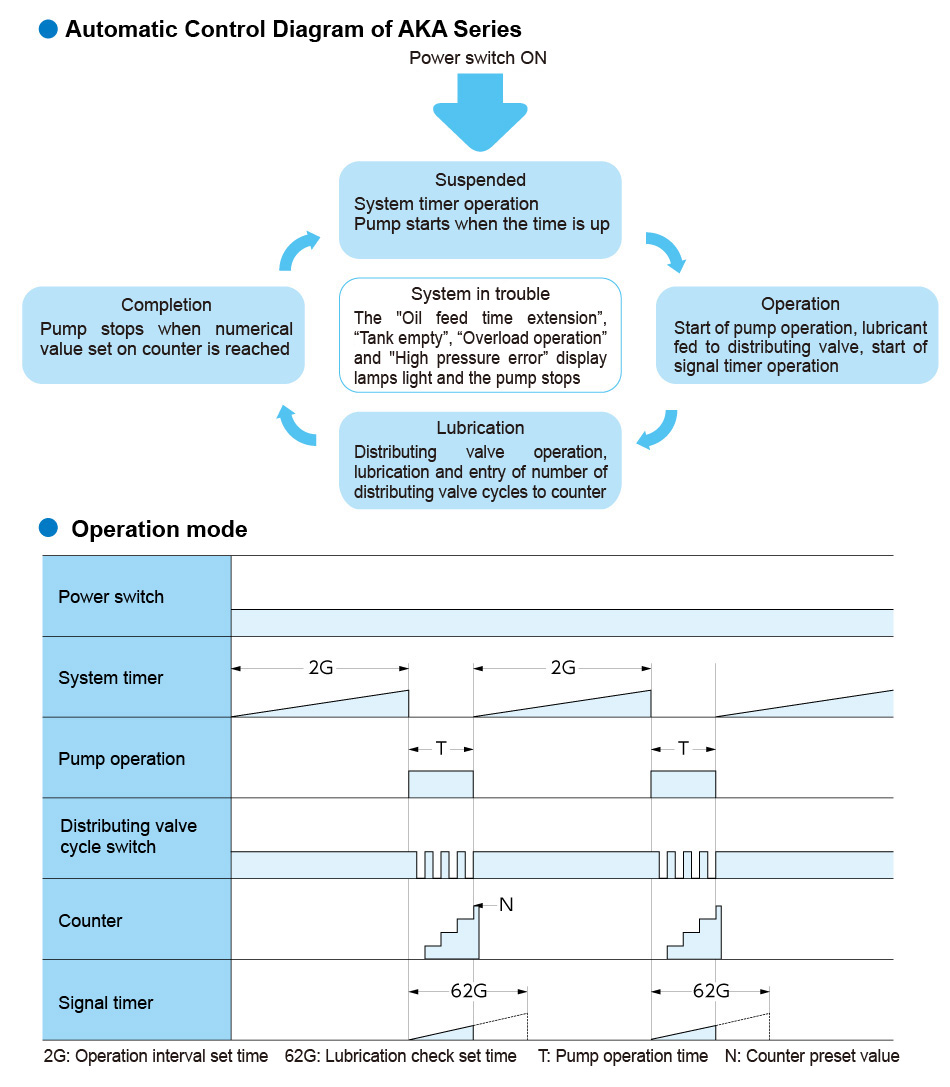

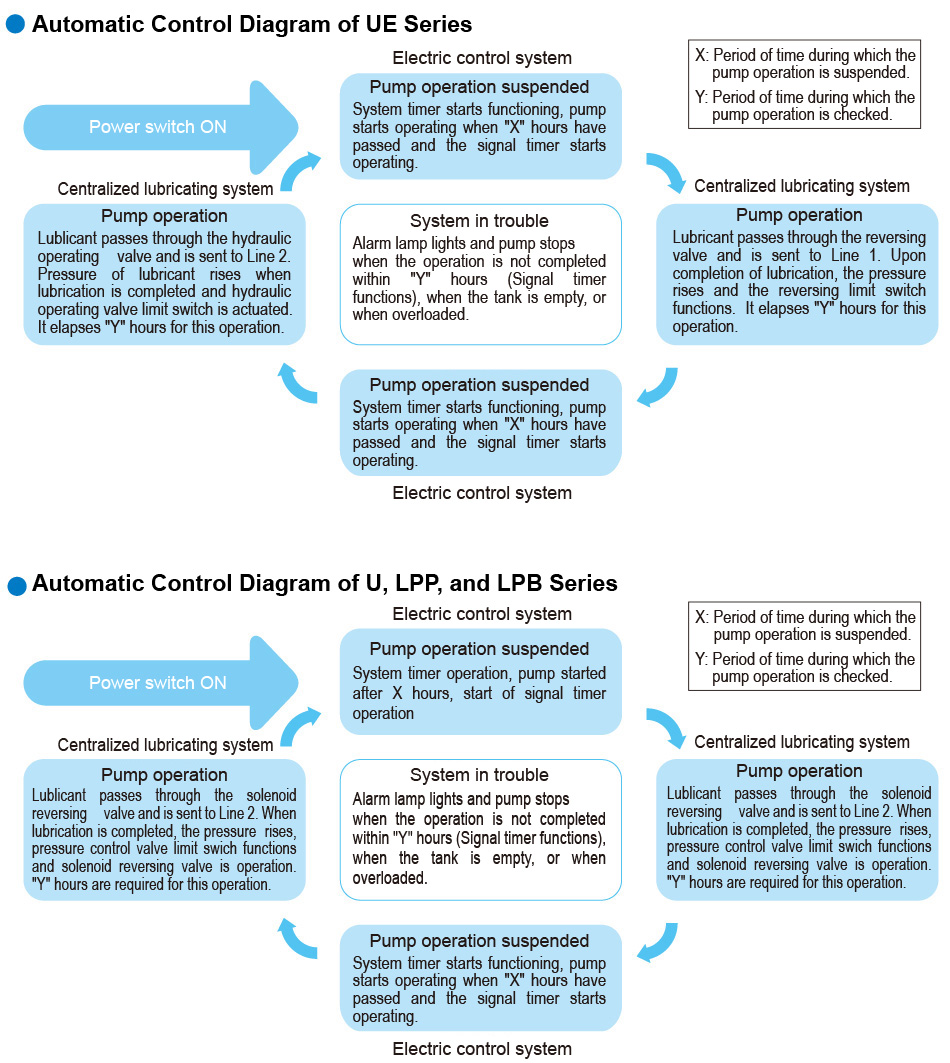

• Operation of the electric control panel

The following diagram simply illustrates the operating statuses of automatic operation.

Single Line Electric Control Panel

• Diagram of automatic controlling of end type system.

The following diagram simply illustrates the operating statuses of automatic operation.