Overview

This motor driven grease pump is used in dual line systems. This pump helps to reduce lubricating system costs by supporting smaller size pipes and wider range lubrication which has resulted from the application of higher pump pressures and larger discharge quantities.

Features

• Proprietary Pump Structure and High Transmission Efficiency Drive Mechanism

• Proprietary Pump Structure

The pump mechanism based on a proprietary piston structure realized twice high pressure and larger discharge quantity even with regular capacity motors. <Patent Obtained> (discharge pressure 21 MPa with 0.75 kW motor → 40 MPa, discharge quantity 194 → 400 cm/min (50 Hz))

• Connection to High-pressure Compatible Piping

Pipe connection port and replenishing port support pressures up to 40 MPa by parallel pipe thread connections.

Specifications

| Model | Max. operating pressure MPa |

Discharge quantity (cm3/min) |

Pump | Gear motor kW x 4 poles | Tank capacity (L) |

Piping system |

Weight (kg) |

||||||

| Rotation speed (min-1) |

Speed reduction ratio |

||||||||||||

| 50Hz | 60Hz | 50Hz | 60Hz | Capacity | Voltage and frequency | ||||||||

| UE-30A※S※※※-10 | 40 | 133 | 160 | 25 | 30 | 1/60 | 0.4kw | 200V 50/60Hz |

220V 60Hz |

90 | End type and Lance type |

300 | |

| 380V 50Hz |

400V 50/60Hz |

440V 60Hz |

|||||||||||

| UE-40A※S※※※-10 | 200 | 240 | 37.5 | 45 | 1/40 | 200V 50/60Hz |

220V 60Hz |

||||||

| 380V 50Hz |

400V 50/60Hz |

440V 60Hz |

|||||||||||

| UE-45A※S※※※-10 | 400 | 480 | 75 | 90 | 1/20 | 0.75kw | 200V 50/60Hz |

220V 60Hz |

|||||

| 380V 50Hz |

400V 50/60Hz |

440V 60Hz |

|||||||||||

*For details on outdoor type, consult us separately.

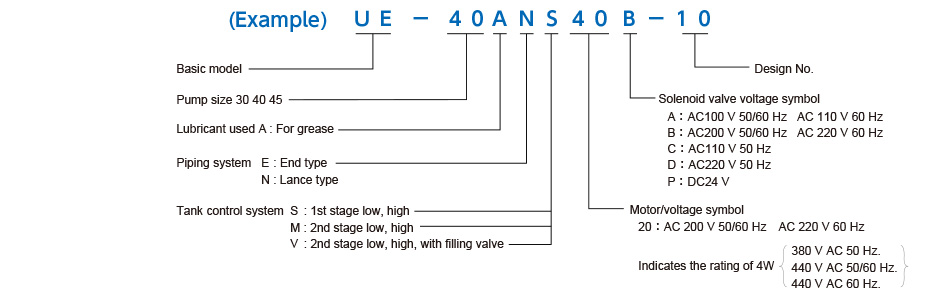

Explanation of Model Symbols

• Before pump operation, fill the crank chamber fitted into the tank bottom with lubricant (gear oil Class 2, VG220 JIS K2219 or equivalent) up to the designated oil level (approx. 5 L) marked in red.

• Replace the lubricant in the crank chamber 200 hours after the start of operation and check every 2,000 hours from then on.

• In this diagram, S: 1-stage low, high is indicated for the tank control system.