![]()

Overview

This pump comprises an elevator unit, that houses the main components (geared motor, solenoid valve (only for dual line) and a pressure switch), a column with built-in gas spring, and a common base.

The pump unit is supported by the gas spring. When replacing the pail can, the pump unit can be raised or lowered by operating this gas spring with little force, which allows the pail can to be replaced without much effort.

Also, the main components are enclosed inside the cover of the elevator unit. This results in a simple exterior and protects components inside from dust and foreign matter.

Features

• As a gas spring is used, the pail can can be raised or lowered by one-touch operation requiring little force. This makes it easy to replace the pail can.

• Both 16 kg and 18 kg pail cans are supported.

• Use of a follower plate enables grease to be used more effectively.

• A level gauge is attached to the pump to allow the amount of residual grease to be checked visually.

• A piston valve system has been adopted to increase discharge performance.

• A strainer is attached at the suction section to protect the pump from foreign matter.

Specifications

| Item/Model Symbol | LPP-08A* | LPP-1A* | LPP-2A* | LPP-3A* | |

| Max. operating pressure | 21MPa | ||||

| Discharge quantity | 29/35cm3/min (50/60Hz) |

38/46cm3/min (50/60Hz) |

58/70cm3/min (50/60Hz) |

83/100cm3/min (50/60Hz) |

|

| Motor output | 90W | ||||

| Power supply voltage | Motor | 100/110 V AC (single-phase) (50/60 Hz) | Not set | ||

| 200/220 V AC (3-phase) (50/60 Hz) | |||||

| 400/440 V AC (3-phase) (50/60 Hz) | |||||

| Applicable pail can | 16 kg and 18 kg pail can | ||||

| Applicable grease | NLGI No.0 to No.2 (Consistency shall be 240 or more at the operating temperature.) | ||||

| Operating temperature range | 0 to 40°C | ||||

| Weight | Single | Approx. 52 kg (excluding pail can) | |||

| Dual | Approx. 58 kg (excluding pail can) | ||||

| Solenoid operating valve (dual line only) |

AC100/100V(50/60Hz) | ||||

| AC200/220V(50/60Hz) | |||||

| DC24V | |||||

| Distributing valve used | Single | M, MX type | |||

| Dual | DV, DW type | ||||

| Number of lubricating ports | Within 100 | Within 150 | Within 200 | ||

Note) All specifications include a setting for single line or dual line.

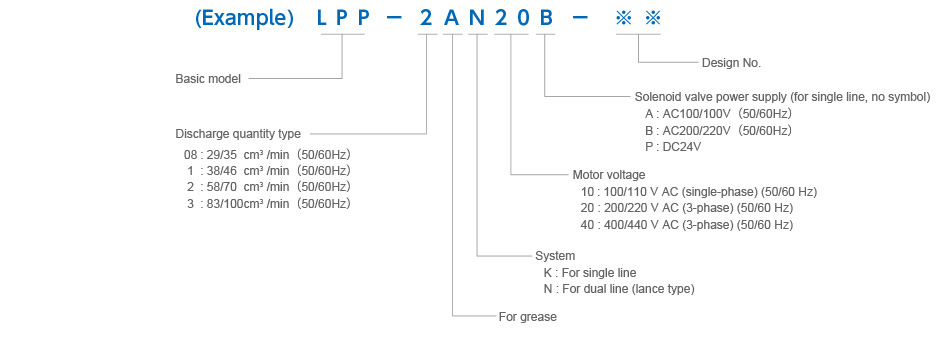

Explanation of Model Symbols