![]()

Features

• Use of a geared motor has resulted in a simpler mechanism. (Outdoor specifications (IP54 or equivalent) have been adopted for the motor.)

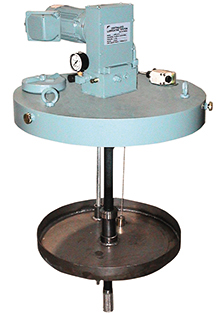

• The mechanism of this pump has been simplified, which means that the pump body alone is a light 65 kg or so.

• Adoption of an optional lifter enables the drum can to be easily replaced.

Note: This pump is basically compatible with the H400 type motor driven pump, which already has a proven track record, consult with us when replacing the H400 pump.

• A replenisher pump is no longer needed as this is a drum can mounted type lubrication pump.

• Attachment of a follower plate has reduced the amount of residual grease and allows grease to be used more effectively.

• Both single line and dual line systems can be supported as models of this pump are available for both systems.

• The suction performance of high-viscosity grease has been improved by adoption of a piston valve system at the suction port and enhancing cut-off performance.

Specifications

| Max. operating pressure (MPa) | 21 |

| Discharge quantity (cm3/min) | According to specification table (75/90 to 316/380) |

| Power supply (3-phase) | AC 200/220 V (50/60 Hz) AC 400/440 V (50/60 Hz) |

| Drum can used | 200 L drum can |

| Grease used | NLGI No.0 to No2. (Note, however, that the consistency shall be 240 or more at the operating temperature.) |

| Piping system | Single line, dual line |

| Model | LBP08 | LBP10 | LBP20 | LBP40 |

| Discharge quantity(cm3 /min(50/60Hz)) | 75/90 | 100/120 | 158/190 | 316/380 |

| Max. discharge pressure (MPa) | 21 | |||

| Safety valve pressure (MPa) | 25 | |||

| Motor specifications | 0.2 kW, speed reduction ratio 1/59 |

0.2 kW, speed reduction ratio 1/43 |

0.4 kW, speed reduction ratio 1/21 |

|

| Accessories | with follower plate, with low level switch, with drum can access door | |||

| Weight (kg) | Approx. 65 | |||

| Number of lubricating ports | 200 | 300 | 600 | 800 |

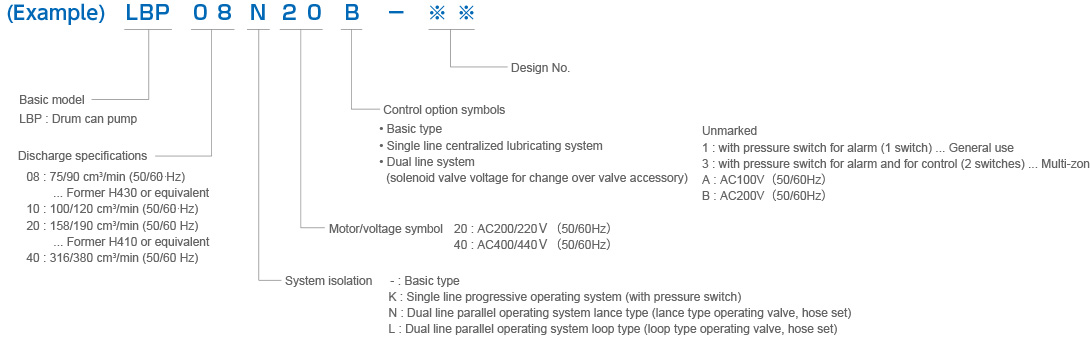

Explanation of Model Symbols