![]()

Overview

This motor driven grease pump is used in dual line systems. It supports larger mechanical equipments and faster speeds to aid the streamlining of facilities.

Features

• Simplified Pipeline

The pipe diameter can be made narrow due to application of higher pump pressure, which helps to save piping costs.

• Compact Size

The pump has a built-in reduction gear and is directly coupled to an electric motor. As a result, this pump is compact and has a small footprint.

• Improved Lubrication Reliability

Lubrication pressure can be further assured by higher pressure, which ensures that grease can be fed reliably to the end of the supply line.

• Lubrication Over a Wide Range

The supply line can be extended proportionately to the lubrication pressure. Consequently, lubrication is possible over a wider (longer) range.

• Low-cost Automatic Lubrication

Automatic operation is possible easily and at low cost by installing an electric control panel (exclusive standard part).

Specifications

| Model | Discharge quantity (cm3 /min) |

Max. operating pressure (MPa) |

Pump rotation speed (min-1) |

Direction of motor rotation |

Electric motor |

Tank capacity (L) |

Crank chamber lubricating oil amount (L) |

Piping system |

Weight (kg) |

|||

| 50Hz | 60Hz | 50Hz | 60Hz | Speed reduction ratio |

Output/kW number of poles |

|||||||

| U-25AN | 60 | 72 | 21 | 100 | 120 | 1/15 (built-in) | Clockwise rotation |

0.4 4P |

25 | 1 | Lance type | 140 |

| U-25AE | End type | |||||||||||

| U-25AL | Loop type | |||||||||||

| U-40AN | 195 | 234 | 75 | 90 | 1/20 (built-in) | 0.75 4P |

35 | 2 | Lance type | 210 | ||

| U-40AE | End type | |||||||||||

| U-40AL | Loop type | |||||||||||

| U-5AL | 585 | 702 | 75 | 90 | 1/20(built-in) | Counterclockwise rotation |

1.5 4P |

90 | 5 | Loop type | 350 | |

| U-5AE | End type | 340 | ||||||||||

Note) 1. When the tank oil amount is automatically controlled, the actual tank capacity decreases by approximately 15%. 2. Continuous rating is applied for the electric motor. Note, however, that the U-45 type is a 10-minute rating.

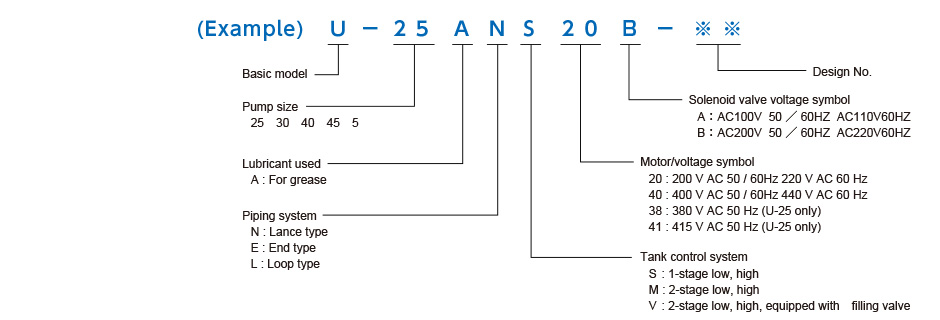

Explanation of Model Symbols