![]()

Overview

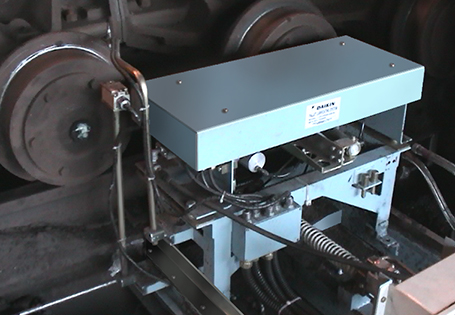

Pallet trolleys and cooler trolleys in sinter plants in ironworks play an important role in continuous manufacturing processes in iron foundries.

This equipment automatically lubricates the wheel bearings of trolleys with an adequate amount of oil during operation to extend the service life of facilities and prevent hazards.

Features

• Extended Service Life of FacilitiesLubrication with an adequate amount of oil prevents wheel lubrication defects, improves the operating rate of facilities, and also can reduce power costs.

• Improved Work Efficiency

The time required for repair and replacement, etc. of the trolley due to defective rotation of the wheels caused by defective lubrication and lifting of the trolley is reduced, which improves work efficiency.

• Labor Savings and Prevention of Hazardous Work

Automatic lubrication can be easily and reliably performed as this feeder is driven by factory air and trolley moving force. This both saves personnel expenses, and prevents hazardous work and missed lubrication.

Specifications

| Air supply pressure | 0.4 to 0.5 MPa |

| Lubricant supply pressure | 5 to 15 MPa |

| Air supply pressure | 1 NL(at 0.4 MPa) |

| Pallet trolley speed | 2.4 to 3.5 m/min |

| Wheel pitch | 740 to 760 mm |

| Wheel diameter | 300 mm |

| Wheel vertical run-out tolerance | ±4mm |

| Wheel horizontal run-out tolerance | ±25mm |

| Discharge quantity | 5 cm3/stroke |

| Adjustment amount per rotation of adjusting screw | 0.15 cm3 |

| Lubricant used Lubricant supply pressure |

NLGI consistency No.0 to No.1 grease |

| Ambient temperature | 5 to 60°C |

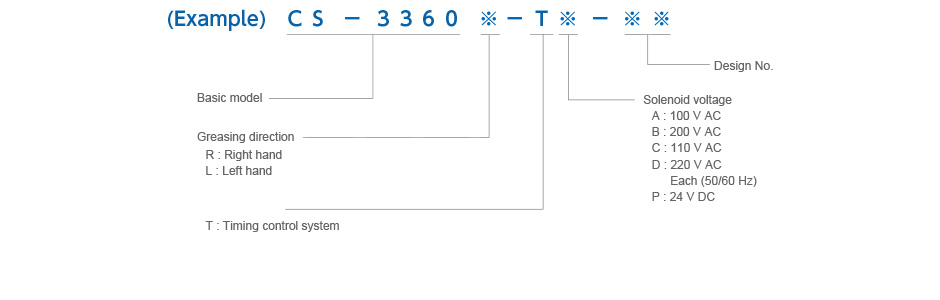

Explanation of Model Symbols